φ219×10 Ioyile kunye neGesi yoThutho (API) Umgca weMveliso yePipe

Inkcazo

I-ERW tube mill ikwabizwa ngokuba yi-high-frequency longitudinal welded pipe line production. Izixhobo ezifanelekileyo zishushu-eshushu okanye ezibandayo ziqengqeleka i-strip coil ezifana ne-plain carbon steel kunye nentsimbi ephezulu, njl.

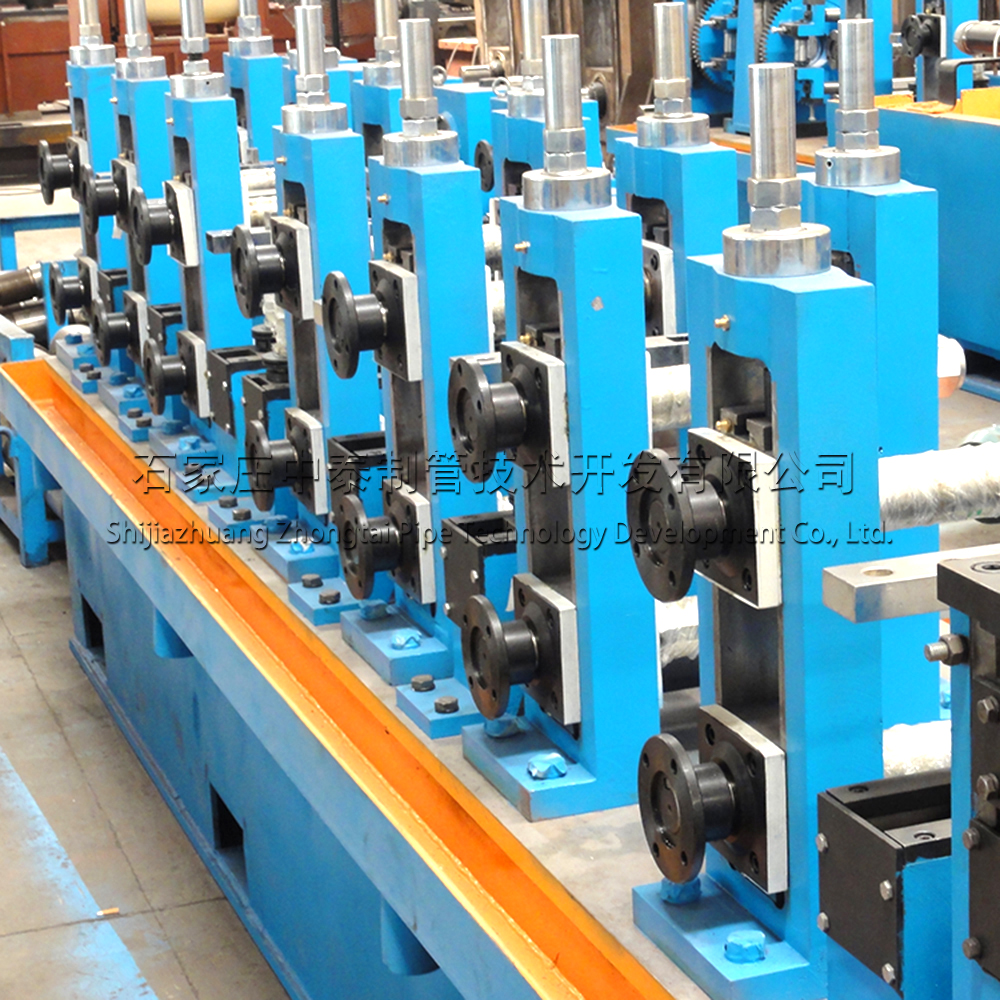

Intsimbi yomcu ivulwa yi-uncoiler, kwaye emva koko ingene kwindawo yokugcina i-accumulator emva kokudlula kumatshini we-shear butt welding. Intsimbi ye-strip ikhutshwe ngama-rollers kwaye ihlulwe ibe ngamacandelo amabini: icandelo lokuqhawula kunye necandelo lokupasa kakuhle. Emva kwe-welding ye-high-frequency induction welding kunye nokulinganisa inxalenye, khupha ubude obufunekayo bombhobho, unqunyulwe ngesarha ephaphazelayo, kwaye ekugqibeleni ubeke kwaye upakishe umbhobho wentsimbi. Lo mgca wemveliso ngumgca wemveliso opheleleyo opheleleyo wokuwelda okuqhubekayo kweentsimbi zentsimbi zibe yimibhobho,ikakhulu yenziwe uncoiler, shear & ukugqiba ukuwelda, i-accumulator, umatshini wokwenza & wokulinganisa, HF welder, isarha esiphaphazelayo, ukupakisha kunye nomatshini wokupakisha.

Ukuba kukho iinjongo ezikhethekileyo okanye iimfuno zemibhobho yensimbi, kuyimfuneko ukongeza izixhobo zokuvavanya, ezifana nomshini wokuvavanya i-hydraulic, umatshini wokudibanisa ama-frequency annealing, umatshini wokukhangela i-ultrasonic flaw, njl.

Umgca wemveliso wombhobho odityanisiweyo ophindaphindiweyo usetyenziswa ikakhulu kwimveliso eqhubekayo yombhobho odityanisiweyo othe ngqo. Yamkela i-welding ye-high-frequency induction welding, engakwazi ukuvelisa umbhobho ojikelezayo kuphela kodwa kunye nepayipi yesikwere esihambelanayo kunye nemibhobho ekhethekileyo. Umatshini we-welding we-high-frequency welding machine usetyenziselwa ukuveliswa kwemibhobho yentsimbi eyahlukeneyo, imibhobho yokwakha, imibhobho yesakhiwo, imibhobho yamanzi, imibhobho yeoli, iMibhobho ye-API, njalo njalo.

Tukuhamba kwezobuchwepheshe

Ukuskrolela phezulu→ Ukuqaqa → Ukucheba kunye nokuWelding→ Isiqokeleli seSpiral→ Ukwenza → ukuwelda kwe-HF → Ukususwa kwebhara yangaphandle→ Ukupholisa → Ubukhulu → Isarha ebhabhayo → Phuma itafile →Ukuhlola→Ukupakisha→ Indawo yokugcina

Finkqubo orming

| Umbhobho ojikelezayo | Inkqubo yokwenza umqulu obandayo | Uyilo oluhle lwe-roller |

| Siquare & umbhobho woxande | Inkqubo jikelele yokujikeleza ukuya kwisikwere | Inkqubo ezinzileyo yokubumba |

| Round-to-square ngentloko yamaTurkey | Umgangatho olungileyo wombhobho |

Ulwazi oluSisiseko lwezobuGcisa lomgca weMveliso yePipe eWelded

| iMveliso kunye neSivuno | Round Pipe | 89mm-219mm ukutyeba:2.0mm-8.0mm |

| Ityhubhu yesikwere kunye noxande | 70mmx70mm -170mm×170mm ukutyeba:2.0mm-6.0mm | |

| Ubude | 6m-12m Ubude bokunyamezela: ± 3mm | |

| Isantya seMveliso | 20-50m/umz | |

| Isakhono seMveliso | 35,000 yeetoni/ngonyaka | |

| Ukusetyenziswa | I-Mill efakwe kwi-Capacity | 280 kw |

| Indawo yomgca | 100m(ubude) ×9m (ububanzi) | |

| Umsebenzi | 6-8 abasebenzi | |

| Impahla engekasilwa | Izinto eziphathekayo | I-Carbon Steel Coil Q235B(ASTM GR·D,σs 230) |

| Ububanzi | 280mm-690mm ubukhulu:2.0mm-8.0mm | |

| Ikhoyili ID | 600-800mm | |

| Ikhoyili OD | Max2000mm | |

| Ubunzima bekhoyili | 8.0t |

Inzuzo

1. Ukusebenza okuphezulu kwemveliso, isantya somgca sinokufikelela kwi-120m / min.

2. Ukuvunwa okuphezulu, umatshini usebenza ngokuzinzileyo kwisantya esiphezulu, esiphucula ukuveliswa kweemveliso.

3. Inkcitho ephantsi, inkcitho yeyunithi ephantsi kunye nexabiso eliphantsi lemveliso.

4. Ukuchaneka okuphezulu, impazamo yobubanzi yi-0.5/100 kuphela ye-OD yombhobho.

Iimveliso: I-GI, i-carbon steel kunye ne-stainless steel tubes ye-metallurgy, ukwakhiwa, ukuthutha, oomatshini kunye namashishini ezithuthi.

| ERW TUBE MILL LINE | |||||

| Umzekelo | Rumbhobho ojikelezayo mm | Isikwereumbhobho mm | Ukutyeba mm | Isantya sokusebenza m/umz | |

| ERW20 | Ф8-Ф20 | 6x6-15×15 | 0.3-1.5 | 120 | Funda ngokugqithisileyo |

| ERW32 | Ф10-Ф32 | 10×10-25×25 | 0.5-2.0 | 120 | |

| ERW50 | Ф20-Ф50 | 15×15-40×40 | 0.8-3.0 | 120 | |

| ERW76 | Ф32-Ф76 | 25×25-60×60 | 1.2-4.0 | 120 | |

| ERW89 | Ф42-Ф89 | 35×35-70×70 | 1.5-4.5 | 110 | |

| ERW114 | Ф48-Ф114 | 40×40-90×90 | 1.5-4.5 | 65 | |

| ERW140 | Ф60-Ф140 | 50×50-110×110 | 2.0-5.0 | 60 | |

| ERW165 | Ф76-Ф165 | 60×60-130×130 | 2.0-6.0 | 50 | |

| ERW219 | Ф89-Ф219 | 70×70-170×170 | 2.0-8.0 | 50 | |

| ERW273 | Ф114-Ф273 | 90×90-210×210 | 3.0-10.0 | 45 | |

| ERW325 | Ф140-Ф325 | 110×110-250×250 | 4.0-12.7 | 40 | |

| ERW377 | Ф165-Ф377 | 130×130-280×280 | 4.0-14.0 | 35 | |

| ERW406 | Ф219-Ф406 | 170×170-330×330 | 6.0-16.0 | 30 | |

| ERW508 | Ф273-Ф508 | 210×210-400×400 | 6.0-18.0 | 25 | Funda ngokugqithisileyo |

| ERW660 | Ф325-Ф660 | 250×250-500×500 | 6.0-20.0 | 20 | Funda ngokugqithisileyo |

| ERW720 | Ф355-Ф720 | 300×300-600×600 | 6.0-22.0 | 20 | Funda ngokugqithisileyo |

| INGXAKI YOMbhobho WOKUVELISA | |||||

| Umzekelo | Rumbhobho ojikelezayo mm | Isikwereumbhobho mm | Ukutyeba mm | Isantya sokusebenza m/umz | |

| SS25 | Ф6-Ф25 | 5 × 5-20 × 20 | 0.2-0.8 | 10 | Funda ngokugqithisileyo |

| SS32 | Ф6-Ф32 | 5×5-25×25 | 0.2-1.0 | 10 | Funda ngokugqithisileyo |

| SS51 | Ф9-Ф51 | 7×7-40×40 | 0.2-1.5 | 10 | Funda ngokugqithisileyo |

| SS64 | Ф12-Ф64 | 10×10-50×50 | 0.3-2.0 | 10 | Funda ngokugqithisileyo |

| SS76 | Ф25-Ф76 | 20×20-60×60 | 0.3-2.0 | 10 | Funda ngokugqithisileyo |

| SS114 | Ф38-Ф114 | 30×30-90×90 | 0.4-2.5 | 10 | Funda ngokugqithisileyo |

| SS168 | Ф76-Ф168 | 60×60-130×130 | 1.0-3.5 | 10 | Funda ngokugqithisileyo |

| SS219 | Ф114-Ф219 | 90×90-170×170 | 1.0-4.0 | 10 | Funda ngokugqithisileyo |

| SS325 | Ф219-Ф325 | 170×170-250×250 | 2.0-8.0 | 3 | Funda ngokugqithisileyo |

| SS426 | Ф219-Ф426 | 170×170-330×330 | 3.0-10.0 | 3 | Funda ngokugqithisileyo |

| SS508 | Ф273-Ф508 | 210×210-400×400 | 4.0-12.0 | 3 | Funda ngokugqithisileyo |

| I-SS862 | Ф508-Ф862 | 400×400-600×600 | 6.0-16.0 | 2 | Funda ngokugqithisileyo |