Imveliso esebenzayo yomgangatho ophezulu we-Electric Resistance Welded (ERW) imibhobho ixhomekeke kakhulu ekudityanisweni kwamacandelo ahlukeneyo abalulekileyo ngaphakathi kwe-ERW tube mill.

I-ERWityhubhu yokusilasisixhobo esintsonkothileyo soomatshini abenzelwe ukuguqula iikhoyili zentsimbi zibe yimibhobho egqityiweyo. Inqanaba ngalinye lenkqubo, ukusuka ekulungiseleleni ikhoyili ukuya ekusikeni kwemibhobho, ibalulekile ekuqinisekiseni imilinganiselo echanekileyo, imfezeko yesakhiwo, kunye nokuveliswa ngokufanelekileyo. Eli nqaku liza kuphonononga amacandelo aphambili e-ERWityhubhu yokusilakwaye baqaqambise iindima zabo ezibalulekileyo kwinkqubo yokwenziwa kombhobho.

Uhambo luqala nge-uncoiler, enoxanduva lokukhulula ngokutyibilikayo nangokukhuselekileyo icoil yentsimbi. I-uncoiler eyilwe kakuhle iqinisekisa ukuhamba okuqhubekayo kunye nokuhambelana kwezinto eziphathekayo kwiIlitye lokusila i-ERW, ukuthintela iijam kunye nokuphazamiseka kwimveliso. Le yindawo yokuqala yohambo lokuvelisa umbhobho, kwaye ukuzinza kwayo kuchaphazela yonke inkqubo esezantsi.

Okulandelayo, icandelo lokubumba leIlitye lokusila i-ERWkulapho umcu wentsimbi usicaba ngokuthe ngcembe umiliselwe kwifomu ye-tubular. Eli nqanaba libalulekileyo lisebenzisa uthotho lweerola ngokuqhubekayo ukugoba kunye nokugoba umcu, ukudala imilo engqukuva efunekayo phambi kwenkqubo yokuwelda. Ulungelelwaniso oluchanekileyo lwe-roller kunye nokulungelelaniswa kubaluleke kakhulu kweli candelo ukufezekisa iiprofayili zepayipi ezihambelanayo nezichanekileyo.

Inkqubo yokwenza kwiIlitye lokusila i-ERWichaphazela kakhulu umgangatho wombhobho wokugqibela. Ukulandela inkqubo yokubumba, icandelo le-welding kulapho imiphetho yentsimbi eyenziweyo idityaniswe kunye.

I-ERW tube mill isebenzisa i-welding ye-high-frequency resistance resistance, idala i-seam eyomeleleyo kunye neyomelele. Ukuchaneka kunye nokulawulwa kwenkqubo ye-welding kubalulekile ukuqinisekisa ukunyaniseka kwesakhiwo sombhobho. Eli nyathelo liqinisekisa ibhondi esisigxina phakathi kwemida emibini yomgca wensimbi.

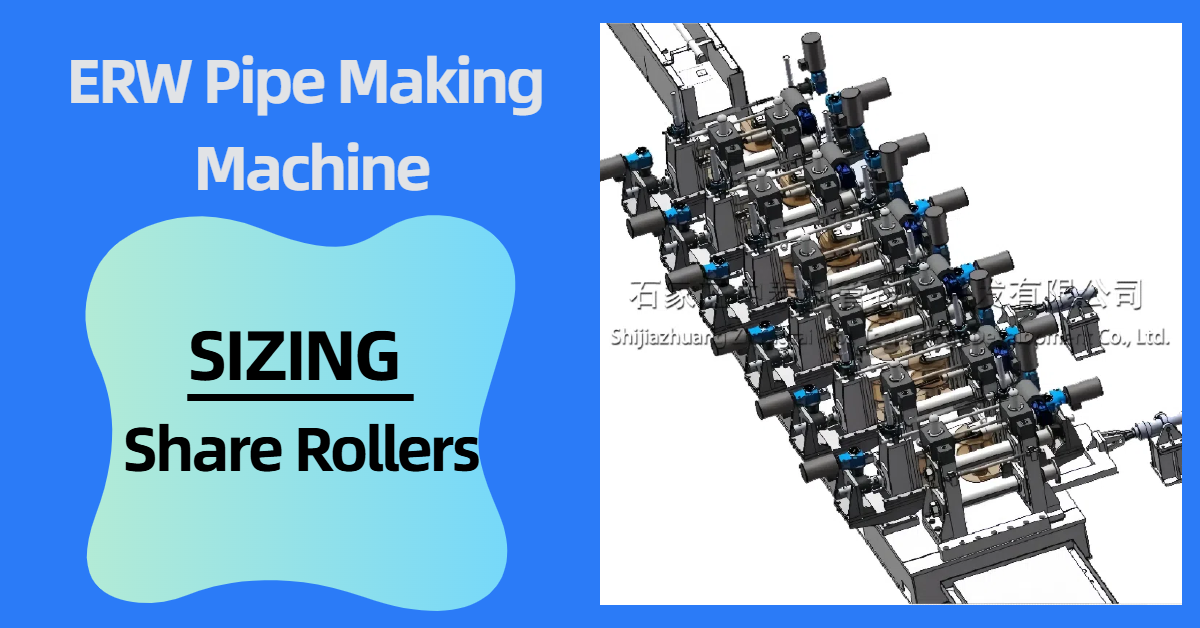

Emva kwewelding, icandelo lokulinganisa leIlitye lokusila i-ERWlungisa kakuhle imilinganiselo yombhobho. Uthotho lweerola ngokuchanekileyo lulungelelanisa umbhobho ukuya kwidayamitha enqwenelekayo yokugqibela kunye nokungqukuva.

Icandelo lokulinganisa libalulekile ekufezekiseni ukunyamezela okuqinileyo kunye nokuqinisekisa ukuba umbhobho uyahlangabezana nemigangatho yoshishino. Eli candelo libalulekile kwimilinganiselo echanekileyo yokugqibela. Icandelo elichanekileyo le-tube mill lisusa nayiphi na i-bends eseleyo okanye iigophe ukusuka kumbhobho odibeneyo.

Iqinisekisa ukuba imveliso egqityiweyo ichanekile ngokuthe ngqo, eyimfuneko ekuphathweni okulandelayo, ukugcinwa, kunye nokusetyenziswa. Eli nqanaba lisebenzisa iirola okanye ezinye iindlela zokususa nakuphi na ukutenxa kumgca othe ngqo, ukudala umbhobho ogqibeleleyo weenkqubo ezingaphezulu.

Ekugqibeleni, i-saw-off-off iyingxenye yokugqibela ye-ERW ye-tube mill, enqumla umbhobho oqhubekayo ubude obuchaziweyo. Isarha esikiweyo kufuneka ichaneke kwaye isebenze ngokufanelekileyo ukufikelela kubude obuguquguqukayo ngelixa kuncitshiswa inkunkuma yezinto. Le nkqubo yokusika ihambisa imibhobho egqityiweyo yokugqibela, ilungele ukuthunyelwa.

Icandelo ngalinye ngaphakathi kwe-ERW ye-tube mill idlala indima ebalulekileyo ekuveliseni ngokufanelekileyo kunye nokuchanekileyo kwimibhobho edityanisiweyo. Ukususela ekukhutshweni kokuqala ukuya ekusikeni kokugqibela, isigaba ngasinye sibalulekile ekuphumezeni umgangatho ophezulu, umbhobho ochanekileyo.

Ukuqonda la macandelo kunye nendlela asebenza ngayo kubalulekile ekuphuculeni ukuveliswa kombhobho kunye nokugcina ukusebenza ngokufanelekileyo kwe-ERW ye-tube mill.

Xa ukhetha i-ERW tube mill, ukuqwalasela ngokucophelela ukuyila kunye nokusebenza kwecandelo ngalinye kubalulekile ekuqinisekiseni ukusebenza kwexesha elide kunye nempumelelo.

Ixesha lokuposa: Jun-28-2024